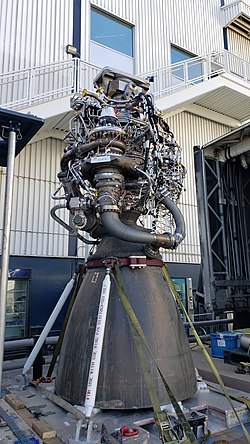

A Raptor 1 rocket engine ready for transport outside SpaceX's factory in Hawthorne, California | |

| Country of origin | United States |

|---|---|

| Manufacturer | SpaceX |

| Status | Currently in use |

| Liquid-fuel engine | |

| Propellant | LOX / CH4 |

| Mixture ratio | 3.6 (78% O2, 22% CH4)[1][2] |

| Cycle | Full-flow staged combustion |

| Pumps | 2 turbopumps |

| Configuration | |

| Chamber | 1 |

| Nozzle ratio | |

| Performance | |

| Thrust | Raptor 1: 185 tf (1.81 MN; 408,000 lbf)[5] Raptor 2: Raptor 3: 280 tf (2.75 MN; 617,000 lbf) |

| Throttle range | 40–100%[10] |

| Thrust-to-weight ratio | 143.8, sea-level |

| Chamber pressure |

|

| Specific impulse, vacuum | 380 s (3.7 km/s)[8] |

| Specific impulse, sea-level | 327 s (3.21 km/s)[9] |

| Mass flow | |

| Burn time | Varies |

| Dimensions | |

| Length | 3.1 m (10 ft)[13] |

| Diameter | 1.3 m (4 ft 3 in)[14] |

| Dry weight | 1,600 kg (3,500 lb)[6] |

| Used in | |

| SpaceX Starship | |

Raptor is a family of rocket engines developed and manufactured by SpaceX. The engine is a full-flow staged combustion cycle (FFSC) engine powered by cryogenic (very low temperature) liquid methane (natural gas) and liquid oxygen, a mixture known as methalox.

SpaceX's super-heavy-lift Starship uses Raptor engines in its Super Heavy booster and in the Starship second stage.[15] Starship missions include lifting payloads to Earth orbit and is also planned for missions to the Moon and Mars.[16] The engines are being designed for reuse with little maintenance.[17]

Raptor is the third full-flow staged combustion engine in history and the first such rocket engine to power a vehicle in flight.[18]

Raptor is powered by subcooled liquid methane and subcooled liquid oxygen in a full-flow staged combustion (FFSC) cycle.

FFSC is a departure from the simpler "open-cycle" gas generator system and LOX/kerosene propellants used by Merlin.[19] RS-25 engines (first used on the Space Shuttle) used a simpler form of staged combustion cycle.[20] Several Russian rocket engines, including the RD-180[19] and the RD-191 did as well.[21]

Liquid methane and oxygen propellants have been adopted by many companies, such as Blue Origin with its BE-4 engine, as well as Chinese startup Space Epoch's Longyun-70.[22] The Zhuque-2 rocket of LandSpace, which in July 2023 was the first methane-fueled launch vehicle to reach orbit.[23]

An oxygen-rich turbine powers an oxygen turbopump, and a fuel-rich turbine powers a methane turbopump. Both oxidizer and fuel streams mix completely in the gas phase before they enter the combustion chamber.[18] Raptor 2 uses an undisclosed ignition method that is allegedly less complex, lighter, cheaper, and more reliable than Merlin's. Torch igniters are used in oxygen and power heads. Engine ignition in Raptor Vacuum is handled by dual-redundant spark-plug lit torch igniters,[24] which eliminated the need for Merlin's dedicated, consumable igniter fluid.[21] Raptor 2 uses coaxial swirl injectors to admit propellants to the combustion chamber, rather than Merlin's pintle injectors.[25][26]

Before 2014, only two FFSC designs had progressed sufficiently to reach test stands: the Soviet RD-270 project in the 1960s and the Aerojet Rocketdyne Integrated Powerhead Demonstrator in the mid-2000s.[27][21][28]

Raptor is designed for extreme reliability, aiming to support airline-level of safety required by the point-to-point Earth transportation market.[29] Gwynne Shotwell claimed that Raptor would be able to deliver "long life... and more benign turbine environments".[30][21]

Raptor is designed for deep cryogenic propellants—fluids cooled to near their freezing points, rather than their boiling points, as is typical for cryogenic rocket engines.[31] Subcooled propellants are denser, increasing propellant mass[32] as well as engine performance. Specific impulse is increased, and the risk of cavitation at inputs to the turbopumps is reduced due to the higher propellant fuel mass flow rate per unit of power generated.[21] Cavitation (bubbles) reduces fuel flow/pressure and can starve the engine, while eroding turbine blades.[33] The oxidizer to fuel ratio of the engine is approximately 3.8 to 1.[34]

Raptor's target performance was a vacuum specific impulse of 382 s (3,750 m/s), with a thrust of 3 MN (670,000 lbf), a chamber pressure of 300 bar (30 MPa; 4,400 psi), and an expansion ratio of 150 for the vacuum-optimized variant. This was achieved with Raptor 2.

Many components of early Raptor prototypes were manufactured using 3D printing, including turbopumps and injectors, increasing the speed of development and testing.[31][35] The 2016 subscale development engine had 40% (by mass) of its parts manufactured by 3D printing.[21] In 2019, engine manifolds were cast from SpaceX's in-house developed SX300 Inconel superalloy, later changed to SX500.[36]

SpaceX's Merlin and Kestrel rocket engines use a RP-1 and liquid oxygen ("kerolox") combination. Raptor has about triple the thrust of SpaceX's Merlin 1D engine, which powers the Falcon 9 and Falcon Heavy launch vehicles.

Raptor was conceived to burn hydrogen and oxygen propellants as of 2009.[37] SpaceX had a few staff working on the Raptor upper-stage engine at a low priority in 2011.[38][39]

In October 2012, SpaceX announced concept work on an engine that would be "several times as powerful as the Merlin 1 series of engines, and won't use Merlin's RP-1 fuel".[40]

In November 2012, Musk announced that SpaceX was working on methane-fueled rocket engines, that Raptor would be methane-based,[41] and that methane would fuel Mars colonization.[28] Because of the presence of underground water and carbon dioxide in Mars atmosphere, methane, a simple hydrocarbon, could be synthesized on Mars using the Sabatier reaction.[42] NASA found in-situ resource production on Mars to be viable for oxygen, water, and methane production.[43]

In early 2014 SpaceX confirmed that Raptor would be used for both first and second stages of its next rocket. This held as the design evolved from the Mars Colonial Transporter[28] to the Interplanetary Transport System,[44] the Big Falcon Rocket, and ultimately, Starship.[45]

The concept evolved from a family of Raptor -designated rocket engines (2012)[46] to focus on the full-size Raptor engine (2014).[47]

In January 2016, the US Air Force awarded a US$33.6 million development contract to SpaceX to develop a prototype Raptor for use on the upper stage of Falcon 9 and Falcon Heavy.[48][49]

The first version was intended to operate at a chamber pressure of 250 bars (25 MPa; 3,600 psi).[50] As of July 2022, chamber pressure had reached 300 bars in a test.[33] In April 2024, Musk shared the performance achieved by SpaceX with the Raptor 1 engine (sea level 185 tf, Rvac 200 tf) and Raptor 2 engine (sea level 230 tf, Rvac 258 tf) along with the target specifications for the upcoming Raptor 3 (sea level 280 tf, Rvac 306 tf)[51][52] and said SpaceX would aim to ultimately achieve over 330 tonnes of thrust on the sea-level booster engines.[53]

Raptor 1 and 2 engines require a heat shroud to protect pipes and wiring from engine heat,[33] while Raptor 3 is planned to no longer need a heat shield.[53]: 18:30

Initial development testing[54] of Raptor components was done at NASA's Stennis Space Center,[16][55] beginning in April 2014. Testing focused on startup and shutdown procedures, as well as hardware characterization and verification.[21]

SpaceX began testing injectors in 2014 and tested an oxygen preburner in 2015. 76 hot-fire tests of the preburner, totaling some 400 seconds of test time, were executed from April-August.[54]

By early 2016, SpaceX had constructed an engine test stand at their McGregor test site in central Texas for Raptor testing.[21][16] The first Raptor was manufactured at the SpaceX Hawthorne facility in California. By August 2016 it was shipped to McGregor for development testing.[56] The engine had 1 MN (220,000 lbf) thrust.[57] It was the first-ever FFSC methalox engine to reach a test stand.[21]

A subscale development engine was used for design validation. It was one-third the size of the engine designs that were envisioned for flight vehicles.[21] It featured 200 bars (20 MPa; 2,900 psi) of chamber pressure, with a thrust of 1 meganewton (220,000 lbf) and used the SpaceX-designed SX500 alloy, created to contain hot oxygen gas in the engine at up to 12,000 pounds per square inch (830 bar; 83 MPa).[58] It was tested on a ground test stand in McGregor, firing briefly.[21] To eliminate flow separation problems while testing in Earth's atmosphere, the test nozzle expansion ratio was limited to 150.[21]

By September 2017, the subscale engine had completed 1200 seconds of firings across 42 tests.[59]

SpaceX completed many static fire tests on a vehicle using Raptor 2s, including a 31 engine test (intended to be 33) on 9 February 2023,[60] and a 33 engine test on 25 August 2023.[61] During testing, more than 50 chambers melted, and more than 20 engines exploded.[33]

SpaceX completed its first integrated flight test of Starship on 20 April 2023. The rocket had 33 Raptor 2 engines, but three of those were shut down before the rocket lifted off from the launch mount. The flight test was terminated after climbing to an altitude of ~39 km over the Gulf of Mexico. Multiple engines were out before the flight termination system (FTS) destroyed the booster and ship.[62]

On the second integrated flight test all 33 booster engines remained lit until boostback burn startup, and all six Starship engines remained lit until the FTS was activated.[63][64]

On the third integrated flight test, all 33 booster engines once again remained lit until main engine cutoff (MECO), and then following hot-staging, 13 successfully relit to perform a boostback for full duration.[65] On the booster's landing burn, only 3 engines of the planned 13 lit, with 2 shutting down rapidly, the other remained lit until a rapid unscheduled disassembly (RUD) occurred ~462 metres above sea level.[65] The ship successfully kept all 6 engines lit until second stage / secondary engine cutoff (SECO) without issues, however a planned in-space raptor re-light was cancelled due to rolling during coast.[65]

|

Main article: SpaceX Starship |

In November 2016, Raptor was projected to power the proposed Interplanetary Transport System (ITS), in the early 2020s.[21] Musk discussed two engines: a sea-level variant (expansion ratio 40:1) with thrust of 3,050 kN (690,000 lbf) at sea level for the first stage/booster, and a vacuum variant (expansion ratio 200:1) with thrust of 3,285 kN (738,000 lbf) in space. 42 sea-level engines were envisioned in the high-level design of the first stage.[21]

Three gimbaled sea-level Raptor engines would be used for landing the second stage. Six additional, non-gimbaled, vacuum-optimized Raptors (Raptor Vacuum) would provide primary thrust for the second stage, for a total of nine engines.[66][21] Raptor Vacuums were envisioned to contribute a specific impulse of 382 s (3,750 m/s), using a much larger nozzle.[67]

In September 2017 Musk said that a smaller Raptor engine—with slightly over half as much thrust as the previous designs—would be used on the next-generation rocket, a 9 m (30 ft)-diameter launch vehicle termed Big Falcon Rocket (BFR) and later renamed Starship.[68] The redesign was aimed at Earth-orbit and cislunar missions so that the new system might pay for itself, in part, through economic spaceflight activities in the near-Earth space zone.[69] With the much smaller launch vehicle, fewer Raptor engines would be needed. BFR was then slated to have 31 Raptors on the first stage and 6 on the second stage.[70][21]

By mid-2018, SpaceX was publicly stating that the sea-level Raptor was expected to have 1,700 kN (380,000 lbf) thrust at sea level with a specific impulse of 330 s (3,200 m/s), with a nozzle exit diameter of 1.3 m (4.3 ft). Raptor Vacuum would have specific impulse of 356 s (3,490 m/s) in vacuum[59] and was expected to exert 1,900 kN (430,000 lbf) force with a specific impulse of 375 s (3,680 m/s), using a nozzle exit diameter of 2.4 m (7.9 ft).[59]

In the BFR update given in September 2018, Musk showed a video of a 71-second fire test of a Raptor engine, and stated that "this is Raptor that will power BFR, both the ship and the booster; it's the same engine. [...] approximately a 200 (metric) tons engine aiming for roughly 300 bar chamber pressure. [...] If you had it at a high expansion ratio, has the potential to have a specific impulse of 380."[9] SpaceX aimed at a lifetime of 1000 flights.[71]

In January 2016, the United States Air Force (USAF) awarded a US$33.6 million development contract to SpaceX to develop a Raptor prototype for use on the upper stage of the Falcon 9 and Falcon Heavy. The contract required double-matching funding by SpaceX of at least US$67.3 million.[48][72] Engine testing was planned for NASA's Stennis Space Center in Mississippi under US Air Force supervision.[48][49] The USAF contract called for a single prototype engine and ground tests.[48]

In October 2017 USAF awarded a US$40.8 million modification contract for a Raptor prototype for the Evolved Expendable Launch Vehicle program.[73] It was to use liquid methane and liquid oxygen, propellants, a full-flow staged combustion cycle, and to be reusable.[49]

In July 2021, SpaceX announced a second Raptor production facility, in south Texas near the existing rocket engine test facility. The facility would concentrate on serial production of Raptor 2, while the California facility would produce Raptor Vacuum and new/experimental Raptor designs. The new facility was expected to eventually produce 800 to 1000 rocket engines each year.[74][75] In 2019 the (marginal) cost of the engine was stated to be approaching US$1 million. SpaceX planned to mass-produce up to 500 Raptor engines per year, each costing less than US$250,000.[76]

Raptor Vacuum[77] (RVac) is a variant of Raptor with an extended, regeneratively-cooled nozzle for higher specific impulse in space. The vacuum-optimized Raptor targets a specific impulse of ~380 s (3,700 m/s).[8] A full-duration test of version 1 of Raptor Vacuum was completed in September 2020 at McGregor.[77] The first in-flight ignition of a Raptor Vacuum was on S25 during the second integrated flight test.[64]

Raptor 2 is a complete redesign of the Raptor 1 engine.[78] The turbomachinery, chamber, nozzle, and electronics were all redesigned. Many flanges were converted to welds, while other parts were deleted.[79] Simplifications continued after production began. On 10 February 2022, Musk showed Raptor 2 capabilities and design improvements.[79][80]

By 18 December 2021, Raptor 2 had started production.[81] By November 2022, SpaceX produced more than one Raptor a day and had created a stockpile for future launches.[82] Raptor 2s are produced at SpaceX's McGregor engine development facility.

Raptor 2s were achieving 230 tf (510,000 lbf) of thrust consistently by February 2022. Musk indicated that production costs were approximately half that of Raptor 1.[79]

Raptor 3 is a further streamlined design of the Raptor engine aimed to ultimately achieve 330 tf (3.2 MN) of thrust in the booster/sea-level configuration,[52] with one stated goal being eliminating the requirement of protective engine shrouds.[53] In May 2023, Musk reported a successful static fire of a Raptor 3 prototype to 350 bar (5,100 psi) for 45 seconds, producing 269 tonnes of thrust.[83] Raptor 3 is a much simplified design that internalizes much of the plumbing and sensors, to increase reliability and improve re-entry performance.[51] In 2024, Musk announced that Raptor 3 was entering the production phase at the McGregor facility.[84][full citation needed]

Raptor 3 engines will not require a heat shield and will have integral cooling and integral secondary flow circuits that run through the various sections of the engine, and it will eliminate many of the bolted joints. This design will be more difficult to service because some parts will be beneath welded joints.[85]: 42:19–45:50

In October 2021, SpaceX initiated an effort to develop a conceptual design for a new rocket engine with the goal of keeping cost below US$1,000 per ton of thrust. The project was called the 1337 engine, to be pronounced "LEET" (after a coding meme).[82]

Although the initial design effort was halted in late 2021, the project helped define an ideal engine, and likely generated ideas that were incorporated into Raptor 3. Musk stated then that "We can't make life multiplanetary with Raptor, as it is way too expensive, but Raptor is needed to tide us over until 1337 is ready."[82]

As of 2024[update], the LEET concept was clarified as a total tearup of the Raptor 3 design, although Musk stated that SpaceX will "probably do that at some point. ... [Raptor 3] looks like a LEET engine, but its way more expensive because it still has printed parts, for example."[85]

|

Main article: Comparison of orbital rocket engines |

| Engine | Rockets | Thrust | Specific impulse, vacuum |

Thrust-to- weight ratio |

Propellant | Cycle |

|---|---|---|---|---|---|---|

| Raptor sea-level | Starship | 2,400 kN (540,000 lbf)[57] | 350 s (3,400 m/s)[86] | 200 (goal) | LCH4 / LOX | Full-flow staged combustion |

| Raptor vacuum | 380 s (3,700 m/s)[86] | 120 (at maximum) | ||||

| Merlin 1D sea-level | Falcon booster stage | 914 kN (205,000 lbf) | 311 s (3,050 m/s)[87] | 176[88] | RP-1 / LOX | Gas generator |

| Merlin 1D vacuum | Falcon upper stage | 934 kN (210,000 lbf)[89] | 348 s (3,410 m/s)[89] | 180[88] | ||

| Blue Origin BE-4 | New Glenn, Vulcan | 2,400 kN (550,000 lbf)[90] | 339 s (3,320 m/s)[91] | LCH4 / LOX | Oxidizer-rich staged combustion | |

| Energomash RD-170/171M | Energia, Zenit, Soyuz-5 | 7,904 kN (1,777,000 lbf)[92] | 337.2 s (3,307 m/s)[92] | 79.57[92] | RP-1 / LOX | |

| Energomash RD-180 | Atlas III, Atlas V | 4,152 kN (933,000 lbf)[93] | 338 s (3,310 m/s)[93] | 78.44[93] | ||

| Energomash RD-191/181 | Angara, Antares | 2,090 kN (470,000 lbf)[94] | 337.5 s (3,310 m/s)[94] | 89[94] | ||

| Kuznetsov NK-33 | N1, Soyuz-2-1v | 1,638 kN (368,000 lbf)[95] | 331 s (3,250 m/s)[95] | 136.66[95] | ||

| Energomash RD-275M | Proton-M | 1,832 kN (412,000 lbf) | 315.8 s (3,097 m/s) | 174.5 | N2O4 / UDMH | |

| Rocketdyne RS-25 | Space Shuttle, SLS | 2,280 kN (510,000 lbf) | 453 s (4,440 m/s)[96] | 73[97] | LH2 / LOX | Fuel-rich staged combustion |

| Aerojet Rocketdyne RS-68A | Delta IV | 3,560 kN (800,000 lbf) | 414 s (4,060 m/s) | 51[98] | LH2 / LOX | Gas generator |

| Rocketdyne F-1 | Saturn V | 7,740 kN (1,740,000 lbf) | 304 s (2,980 m/s)[99] | 83 | RP-1 / LOX | Gas generator |